Cryogenic gasifiers. The gasification installation.

Газификационные установки или газификаторы - это установки, предназначенные для хранения и газификации сжиженных криогенных продуктов (например, кислород, азот, аргон) с последующим заполнением баллонов и других ёмкостей, либо выдачей непосредственно в технологическую линию.

Gasification gasifiers installed or is the installation intended for storage and gasification of liquefied cryogenic products (e.g., oxygen, nitrogen, argon) with subsequent filling of bottles and other containers, or results directly in the production line.

In some cases, economically feasible to make the delivery of cryogenic products in the liquid state. This is due to the following:

- First, the liquid, on average, 700 times denser than gas at normal conditions, which reduces the volume and weight of containers for storage and transport;

- Second, the possible accumulation and storage of large masses of cryogenic products in liquid form by gasification in the process of issuing to the consumer.

The increased use of liquid cryogenic products has led to the need to create systems for storing and dispensing products to consumers with the required parameters - gasification plants.

There are two main types of gasifiers: high and low pressure. Gasification of the cryogenic fluid at high pressure is made by pumping, at low pressure without the pump. This equipment is produced by both stationary and in transport performance. Used for filling of liquid products cold gasifier (GC).

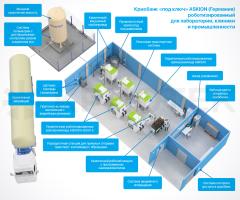

Depending on the destination, size and design features, there is also the classification into groups:

- Stationary;

- Transport;

- Laboratory, the volume and weight which allows you to move them manually.

Gasifiers without the pump to provide a large gas flow (up to 2000 m3/h) pressure up to 1.6 MPa. Warm gasifiers, which are used to produce small amounts of gas under high pressure, is not designed for long-term storage of liquid, and the cold gasifiers allow you to store the liquid cryogenic product for a long time. Because of the large loss product warm gasifiers justified to use only in small laboratory units.

Refill the tank with liquid product as possible from air separation plants and transport containers.

Gasifier type GC differs from the gasifiers MCC by the presence of the evaporator of pressurization to the tank and the second tank, and mobility.

Our company is widely represented universal cryogenic gasifiers, medium and high pressure series CryoCyl, EuroCyl, PermaCyl for storage, transportation and gasification of liquid products of air separation. They find wide application in laboratories, food and electronic industries, medical institutions and other areas of application of cryogenic liquids and gases.

.svg)